This single-layer effect is significant when compared with high line pull conditions in a conventional drum winch in which cable works on itself as a result of multiple layer wraps. While a drum for a hoist is technically a winch it has been my experience that a piece of equipment called a winch has a much smaller drum diameter relative to the cable size.

Sheaves And Drums Python Wire Rope

Construction Mining Terminal operation.

. Groove geometry is determined by rope construction diameter and length and by application. Winch drum hoist drum and crane drum for sale from Dongqi Hoist and Crane the manufacturer and supplier of types of cranes electric hoists winches at good priceDongqi offer custom winch drum design hoist drum design and crane drum design for your need. See Figure 4 The left groove is the traditional ring groove.

Lebus has supplied NFM with parallel grooved sleeves for these winch drums. Grooved Drum on sales - Quality Grooved Drum supplier. Mining LBS Groove Design With Pulling Cable or Wire Rope Reel Drum In Varied.

Design Requirements for Offshore Hoist Drums Introduction 21 Hoist Drum Design The drum is made up of a barrel to wind the rope and where it is not practicable to accommodate all the rope in a single layer a flange is fitted. Here you can find more Custom design rope winch drumcable winch drum details Electric Or Hydraulic Hoist Winch Rope Drum Hoist Winding Groove Drum from Shijiazhuang Jun Zhong Machinery Manufacturing Co Ltd in China. Carbon Stainless And Alloy Steels.

Galvanized Wire Rope Drums with bigger groove for Cable Storage. Empty winch weights range from 300 lb. Winding Not Disorderly Winding LEBUS Groove Multi Cable Drum Multi drum winch In order to meet the requirements of drilling technology and transportation the winch is usually designed as a multi-shaft drive and separate transportation which not only makes the system complex but also increases the cost and installation workload.

Lightweight design winding drums stress and strain. Lebus also adjusted the level winders which is a mechani-cal rope guide system and changed the gear ratio to match the number of pitches on the Lebus groove. Each vessel has two 400t capacity winches.

High quality SS355 Material Grooved Winch Drum Wire Rope Hoist Drum Design Customized from China Chinas leading cable winch drum product with strict quality control rope winch drum factories producing high quality rope winch drum products. Opening angles below 35 must be avoided. Which do you need winch drum hoist drum or crane drum.

Pitch diameter p 5. A m q. The drum V-groove design which is not consistent with the recommendations of the Wire Rope Users Manual maybe acceptable for light loads.

Structural Reliability Assessment of a Winch Drum for an Offshore Crane Leslie L Moyo _____ Chapter 2 Literature review. These are being produced in Le Creusot France by NFM Technologies. Groove is small in traditional V-shaped groove friction roll.

Groove depth 2065 x groove radius h 0374 x d 2065 x 74mm 0374 x 148 15281mm 55352mm 6. Many crane models have a two sided grooved drum one part of it is left the other right lay grooved. 1 over the actual wire rope diameter.

High Efficient Tower Crane Engineering Wire Rope Winch Drum Single Drum. As shown in Fig1 the friction roll can be designed as a narrow V-shaped groove roll so that the rope contacts both sides of the groove firmly which increases the equivalent friction coefficient 9. Construction Mining Terminal operation.

15 x d or d x 2. Ad 12 Years Manufacturing Experience Professional Design RD Team 80 Engineers. Stable Quality Competitive Price Fast Delivery Global Supply Contact Us.

Pitch circle diameter is 27m and the Totals FPSO winches length between flanges is 17m. Diameter of drum Ddrum ratio between 20 to 25 x drope 20 x 14 280 mm 2. However heavy tensile loads will result in severe pinching of the wire rope and galling of the drum groove especially with a lubricant-starved 304 stainless wire rope.

1The advantages of multilayer winding. Groove diameter d 053 x d groove radius x 2 053 x 14mm 74mm x 2 74mm 148mm 4. LBS Groove Or Spiral Groove.

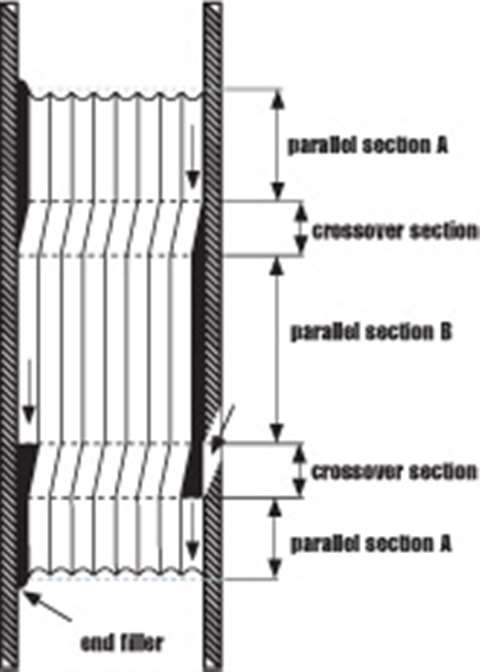

When the wire rope need to wind many layers the LBS groove can fix the crossover point of the upper rope and the lower rope through crossed groove which could control the crossover point and make it finished in the crossed groove. While the right groove is designed into the concave-groove with the arc surface on two sides and being slotted at the bottom. The stress of a winch drum wound with multiple layer of rope is governed by the elastic interaction of.

Rope drums with grooves cut directly into themWinch drum with flange the LBS groove is cut directly into the body of the drum according to customers requirements the flanges are either welded or screw-bolted. Wire Rope Drum With LBS Groove Sleeve Bolted For Crane Towing Winch. Winch loads are light and infrequent.

Traction winch system sheaves absorb high line pull loads by allowing the cable to work in a formed groove at the required minimum bend diameter. Radius difference ri is created between the groove sections. Groove radius r 3.

This change of the winding radius rl. Applications with deflection angles of more than 15 use 60 opening. The side-by-side two drum unit aboard the icebreaker Nathaniel Palmer The term Single Drum Winch can be a misnomer since two or three Load Drums can be combined on a single structure in side-by.

By changing the slotting angle at the bottom of the ring slot θ1 the concave-groove of the friction coiling block with different. It depends on lifting height frequency of use and even the rope diameter as to the type of wire. LBS Sleeve Drum Enginee Machine Suitable To Wokover Rig Logging Electric Device.

Deep Mining Winch With High Effency. Drum core Flanges Shaft Etc. It is composed of two parallel grooves and two crossed grooves in each circle of the winch drum.

WINCH DRUMS FOLLOWING LIGHTWEIGHT DESIGN PRINCIPLES P. The equivalent friction coefficient is obtained by. Winches Lebus simply welded new split sleeves on to the drum together with false flanges to make the length of the drum match the new grooving and compensation plates.

ä t L q g l. High Efficient Tower Crane Engineering Wire Rope Winch Drum Single Drum. For example weve all seen winches on the front of pick-up trucks with 14 diameter wire rope and a drum diameter of about 4.

This applies to smooth as well as to grooved drums. For normal applications use 35 to 45 opening. Be sure to use the correct rope lay direction for the drum.

Minimum 053 to 0535 x d Maximum 055 x d Recommended. Some wire ropes are more sensitive to this type of design than others. Marine Windlass Boat Winch Grooved Drum Carbon Steel Integral Type.

Winch drum hoist drum and crane drum. Each winch will hold 450m length of 118mm diameter wire rope in four layers. Offshore Platform Crane Machine winch Drum For Lifting With Grooved Design.

Drums Grooved Smooth Arizona Wire Rope

Sheave And Drum Dimensions Python Wire Rope

Crane Rope Drum For Sturdy Crane Spare Parts Of Dqcranes

Winch Drum Hoist Drum Crane Drum Drum Design And Manufacturing

0 comments

Post a Comment